Molde de pré-moldagem de boca larga

Informação básica

Modelo: Hot runner preform mould

Descrição do produto

Ciclo rápido devido a circuitos de refrigeração especialmente projetados. Sensores de ejeção de pó que monitoram a transferência de pré-formas para a placa de decolagem, melhorando o tempo de ciclo

Componentes de moldes intercambiáveis padrão, peças de reposição disponíveis dentro de 24 horas

Confiabilidade

Design robusto para longa vida

Ascas auxiliares que reduzem o desgaste do molde pre-alinhando as metades do molde antes do encaixe dos anéis do anel do pescoço

As câmeras de rolo atuam tanto as ações de abertura quanto de fechamento nas divisões da linha

Qualidade da peça

O menor peso de cavidade a cavidade e a variação dimensional como resultado das melhores máquinas e processos de fabricação de fabricação

Mangueiras de água que são colectadas no fundo do molde de pré-moldagem do canal quente, eliminando o potencial de marcas de água nas pré-formas

PET Preform Mould Main Components Specification and Advantages | |||||||||||||||||||||||||||||||||||||||

Main component |

Specification and Advantages |

||||||||||||||||||||||||||||||||||||||

Core |

2316 steel from Sweden |

high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

|||||||||||||||||||||||||||||||||||||

Neck |

S136 steel from Sweden, HRC >60, International standard screw neck |

||||||||||||||||||||||||||||||||||||||

Cavity |

2316 steel from Sweden Each cavity have an independent temperature controller Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm |

||||||||||||||||||||||||||||||||||||||

Body |

P20 Steel material from Germany |

||||||||||||||||||||||||||||||||||||||

Hot runner plate |

2344 Steel material from Germany

|

||||||||||||||||||||||||||||||||||||||

Slider Plate |

wear-resistant copper |

||||||||||||||||||||||||||||||||||||||

specially designed cooling circuits |

Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute |

||||||||||||||||||||||||||||||||||||||

Hot runner design |

make sure the high quality of preform products. |

||||||||||||||||||||||||||||||||||||||

Heater |

Anole Germany |

||||||||||||||||||||||||||||||||||||||

valve gated design with Automatic drop |

each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. |

||||||||||||||||||||||||||||||||||||||

Precessed by high presion CNC machine and numerical control loathe machine |

Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

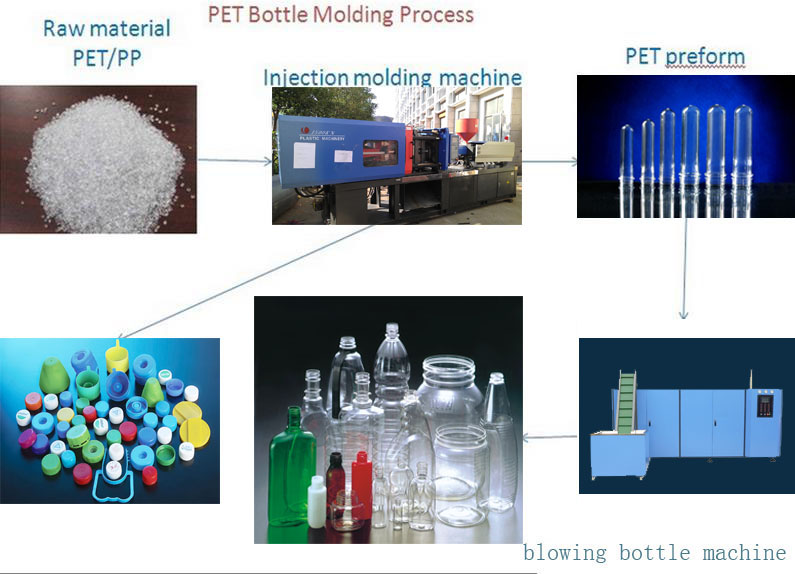

Grupo de Produto : Molde de pré-forma Premium Related Products outros produtos

produtos quentes Máquina de moldagem por injeção a mão 200t / máquina de moldagem por injeção de garrafasMolde de plástico de injeção, molde de plástico, molde de pré-moldagemMolde de injeção de 28 mm / molde de pré-moldagem de plásticoMáquina de enchimento automática garrafa PET de 5 galõesSistema de osmose reversaDesign de garrafasMolde de tampão de garrafa de 48 cavidadesMáquina de sopro semi-automática de duas cavidadesMáquina de moldagem por sopro totalmente automático (6 cavidades) Sobreposição de fábricaMáquina de moldagem por injeção de tubo de pvc de 438tonsPreço da máquina de moldagem por injeção plásticaMáquina de moldagem por injeção preço HDX2000 IIMÁQUINA DE MOVIMENTAÇÃO DE INJEÇÃO PREFORO DE BOTELLAS DE ANIMAL DOMÉSTICO HDX208PET PARA PEQUENO VOLUMEMolde de pré-moldagem de estimação de alta qualidade pronto feitoHDJS128 máquina de fabricação de seringas descartavel de alta qualidade de alta qualidadeMáquina de moldagem por injeção de barbear | ||||||||||||||||||||||||||||||||||||||